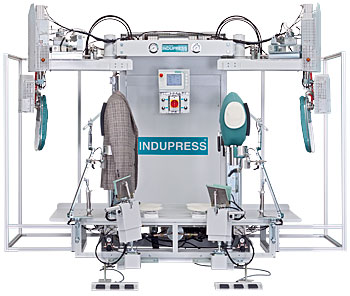

Sleeve setting and finishing

Men's jackets / Finishing pressing department

Special pressing machine for setting and finishing of sleeves on men's jackets with patented, pneumatic variable body for small and big sizes, adjustable to three size ranges (e.g. 46-50, 52-56, 58-64 and bigger).

Three changeable sets of setting stamps for this three size ranges in addition one set of setting stamps for extremely small sizes and armholes

SPECIAL FRAME - right and left shape mounted on one frame

With this machine the body (for setting) can be adjusted to the size of the setting stamp.

Also the shoulder obliquity of the jacket body is variable, easy mechanical, adjustable in order to hang up the jacket perfect fitting to the model and in order to justify the balance.

The finishing pressing device for upper arm which is mounted on top of the machine frame can be passed around the sleeve and so finishes the sleeve completely. The direction can be programmed user-defined, to right/left and high/low.

A very flexible, to all directions adjustable side part holder supports the exact positioning of the jacket.

Because of the back part holder with pneumatic positioning you will get a flat back at the armhole.

Standard equipment

- microprocessor control [ details ]

- USB flash drive for data transfer and data storage

- pressure regulation programmable steplessly (digital)

- steaming and blowing in the whole finishing area

- vacuum and blowing in the armhole area for setting the sleeve

- coverings

- safety device

- complete technical documentation

Additional equipment

- iron incl. safety placing area and accessories, completely pre-assembled

- workplace illumination

- remote maintenance (modem)

Pressing shapes

- especially developed and designed for the respective pressing operation, for ergonomic and high-quality ironing

- custom-fit, digitized and milled

- steam-heated

- evenly vacuum and steam distribution

![]()