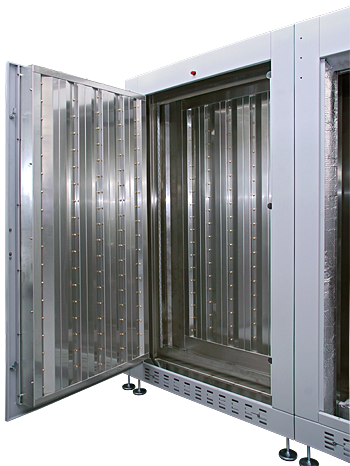

Inside the steam modules the garments absorb enough steam to achieve good results even at high speeds . Also at garments made out of natural fibre.

Each steam module has a length of 1,40 m and consists of

- 10 steam jet rows with total 176 maintenance free steam jets

- + 5 wide-angle jets at the bottom of the tunnel finisher = 181 steam jets per steam module

Special features of the steam system:

- constant steam distribution through new generation of steam jets

- no stripes on the garment

- switched-on steam jet rows at the entry/exit of the steam chamber

- better steam influence to the finishing part

- influence also to else not good accessible areas of the finishing part (side part seams)

- control of the steam pressure at the steam jets

- absolutely constant steam pressure, also at fluctuating net

- programmable humidity of steam

- better finishing result especially for natural fibres

- connection of the steam jets in the lower third of the steam module

- floor heatingdampfmodul innenansicht

- excessive humidity will be vaporized and taken on the garment again

- control of the steam entry pressure

- non-stick-coating of the steam chambers with nanotechnology

- warm air-seal-bags

- avoid steam losses at the tunnel entry

- dosed suction of surplus steam through steplessly controlled exhaust unit

- sucked off energy will partially returned to the finishing part and the system

- heating and filling of the air-seal-bags with residual heat

- hanger guidances at the entry/exit of the tunnel

- hangers can not twist

- turn back of already twist hangers (no blocking of the feed unit)