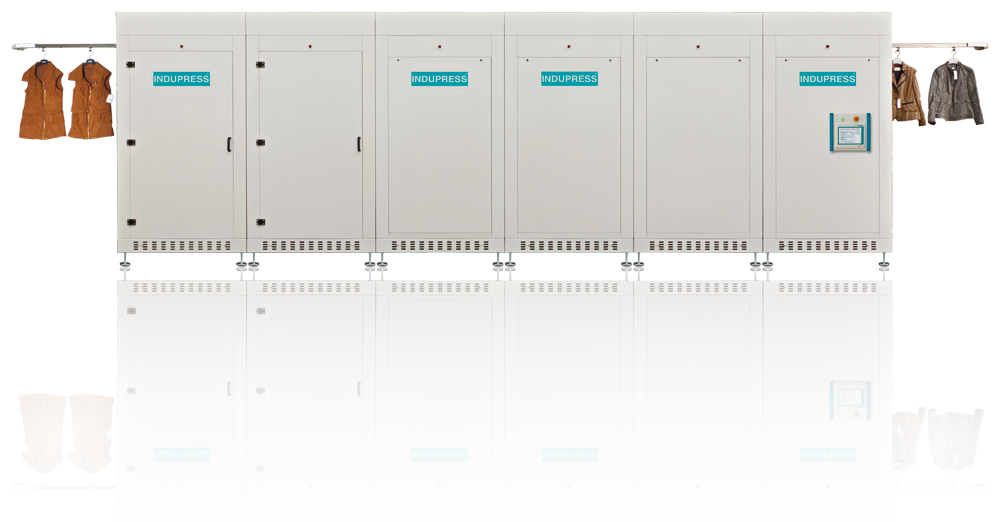

The INDUPRESS® high performance finishing device is constructed in modular version and can be assembled and operated in optimum way for different performance requirements and therefore offers an universal field of application for all garments like blouses, skirts, dresses, coats, trousers, anoraks, clothing for children, T-shirts, sweatshirts, sportswear, pad clothing, thermo jackets and so on.

Highlights of our Tunnelfinisher:

- maintenance-free steam jets

- mineral fully insulation

- universal, customized planning into existing systems (flexible transport system)

- hanging distance in 15 cm steps selectable

- nano-coated surfaces in the steam chambers for easy cleaning

- powerful cross-flow blower for constant treatment of the finishing part

- less power and energy consumption

- overhead clearance approx. 2m (e.g. for evening dresses)

- intelligent energy saving system - automatic, immediate switch-off of the steam spraying as wel as reducing of the blower capacity during Standby operation

- Easy to service - good accessibility of all elements, which have to be maintain or cleaned regularly (large and precisely closing service doors with magnetic lock grant an easy access to the lint filters, heat exchangers, steam valves, condensate traps and pressure regulators)

- Insulation - mechanic separation of the hot inside sheets of the cabinet through high-tech insulation material -> low heat transfer

Process technology

The fibres of the fabrics get soft with a measured and well directed amount of steam.

In the next step the fabrics will be treated from top to bottom with air, fluid flow speed and temperature. All parameter can be adjusted individually and steplessly.

A good finishing result can be achieved by a well balanced programming and exact dosage of the influential finishing parameter for different materials.