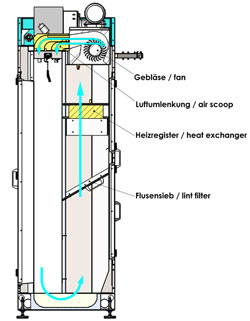

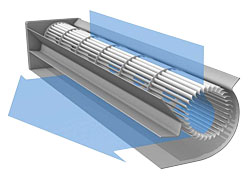

At the new tunnelfinisher generation we use the Direct-Air flow-Method. Against conventional radial fans we use cross-flow fans which assure a constant good finishing result.

Each finishing module has a length of 1,4 m

Special features:

- optimum fluidic design of the air flow

- very high finishing quality, capacity and efficiency

- comfortable sound level

- frequency controlled drive of cross-flow fans, individually for each module

- control of the air flow to each article by program

- no displacing of the finishing part on the hanger through high air flow to the front of the garment - adjustable according to the hanging side

- avoids higher air temperatures at the hanger which avoids it's deformation

- powerful cross-flow fans

- the complete stream energy will be used effective and allow high stretching power on the complete height of the chamber

- powerful heat exchanger made out of stainless steel

- reaching higher temperature (e. g. for leather)

- height-adjustable curtain at the exit of the tunnelfinisher with bloat mechanism from the bottom

- ergonomically positioned dust filter

- on request we can also mount one or several pretreatment modules before the steam area